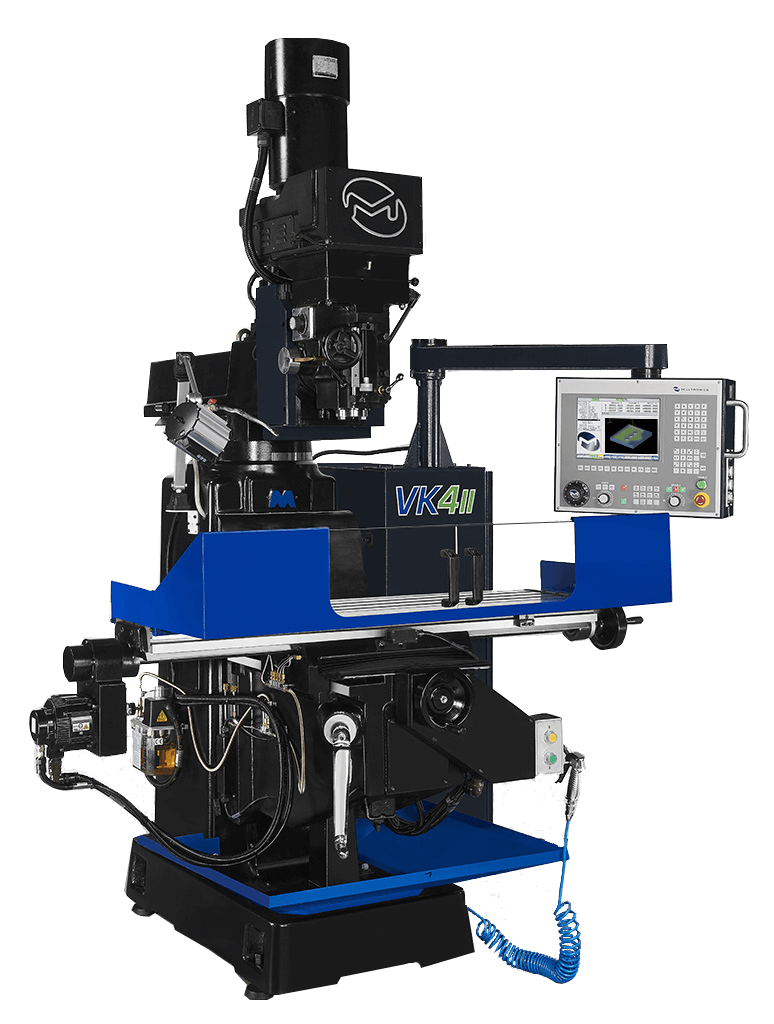

The VK4II is a full 3-Axis CNC knee mill with the unique Milltronics MillSlideTM that provides greater rigidity and more spindle nose to table top than conventional knee mills. With 33″ x 14.25″ x 5.25″ (MillSlideTM), 16.5″ knee and 5.83″ quill travel, the VK4II can be run as manual, teach or full CNC.