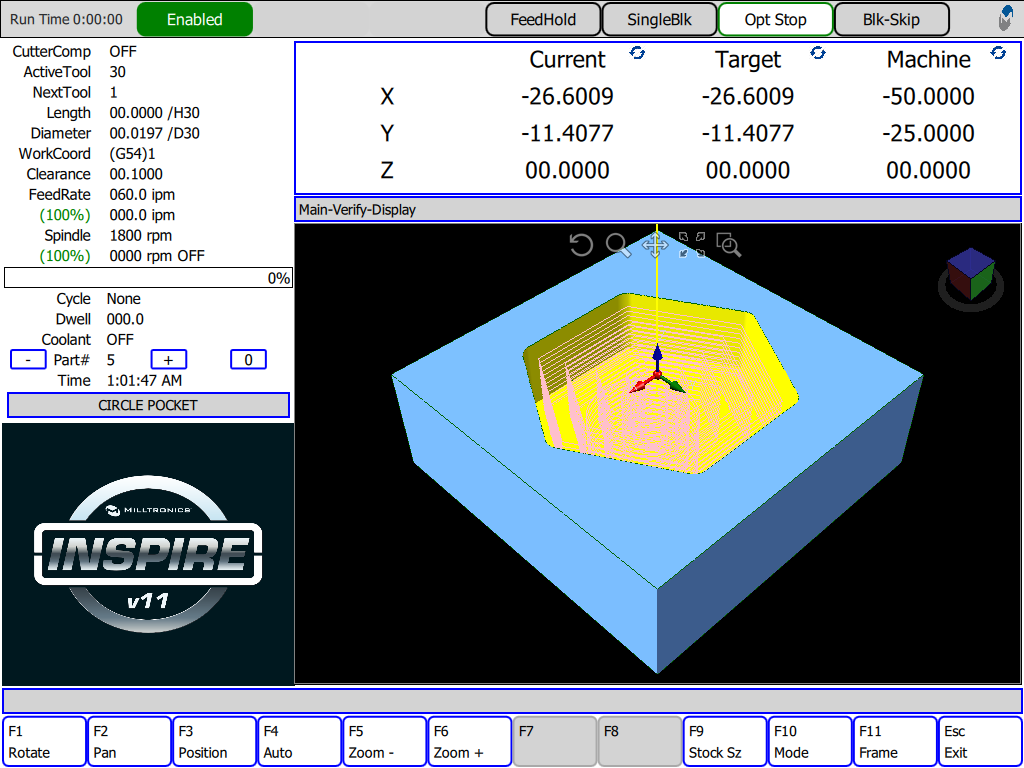

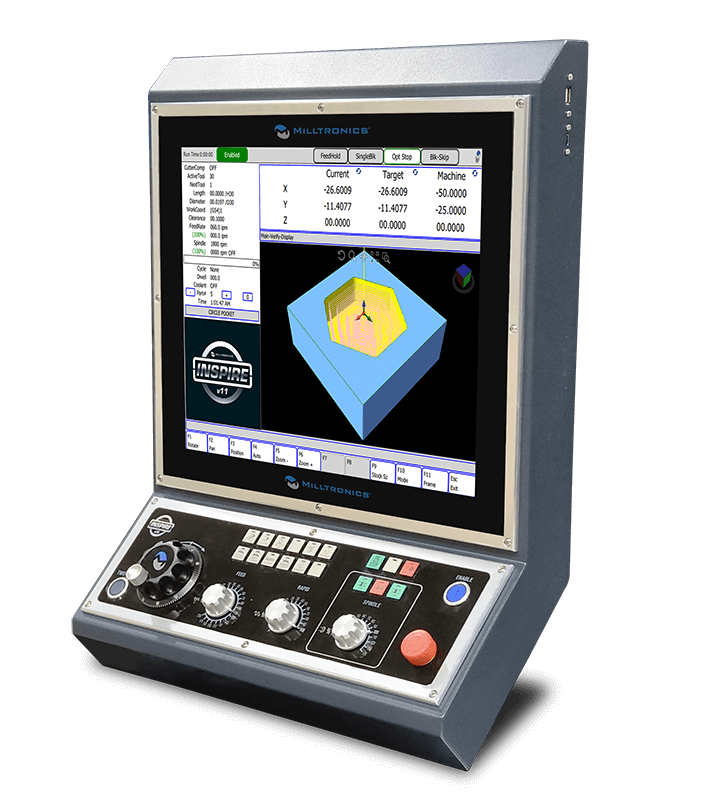

Introducing INSPIRE+ v11 – the ultimate shop floor CNC operating system. This cutting-edge software boasts improved surface finish and cycle times, an advanced proprietary motion engine, and is capable of supporting future machine technologies. With new Industry 4.0 and IoT support, a faster graphics engine, and enhanced customer service capabilities, INSPIRE+ v11 is the complete package.

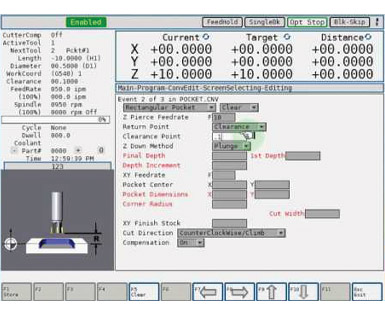

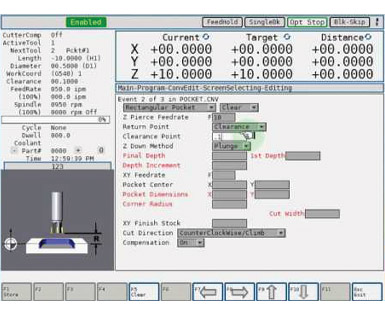

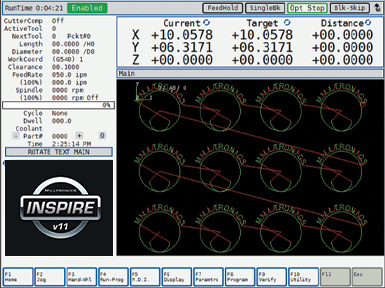

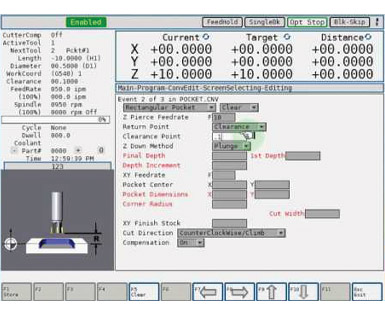

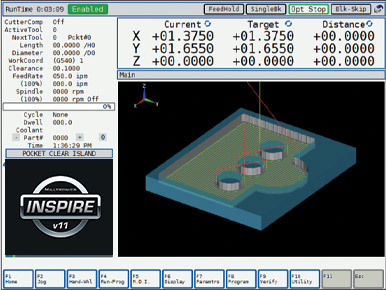

A high efficiency conversational pocketing feature available for all new Milltronics CNC milling machines. Benefits include faster cycle times, improved tool life, and less wear on your machine tool. ChipBoss™ is a modern cutting strategy allowing for higher metal removal rates by increasing the depth of cut while controlling the allowable cut width, reducing cycle times, extending tool life and reducing wear on your machine tool. It is not uncommon to use a depth of cut equal to 3 times the tool diameter with the spiral fill toolpaths generated by ChipBoss™. This cutting strategy originally available only on high end CAM packages is now available conversationally on profiles, open pockets, and pockets with islands. Combine it with tapered wall and Rest Roughing on your Milltronics DGI control and multiply your machine’s productivity.

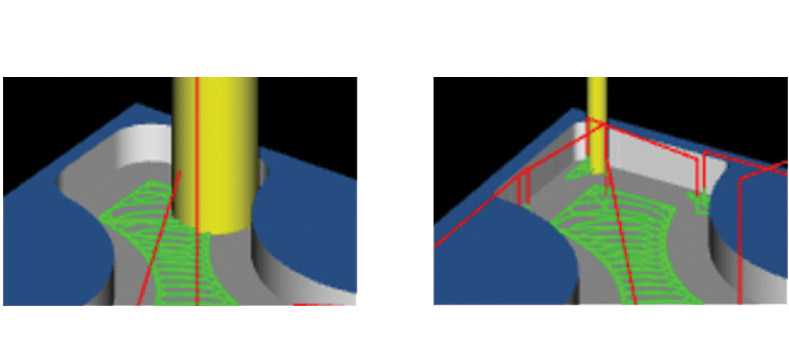

This is a standard conversational feature on all new Milltronics CNC milling machines. With Rest Roughing a large diameter cutter is used to quickly remove material from a pocket or profile and then one or more smaller cutters are used machine away only the material that the large cutter could not reach. Best of all, the control does all the work for you, automatically computing what material the previous cutter left behind. In the example shown, Rest Roughing improved cycle time by more than 33% using a 0.50” D end mill followed by the 0.25” cutter, over just using the 0.25“cutter alone.

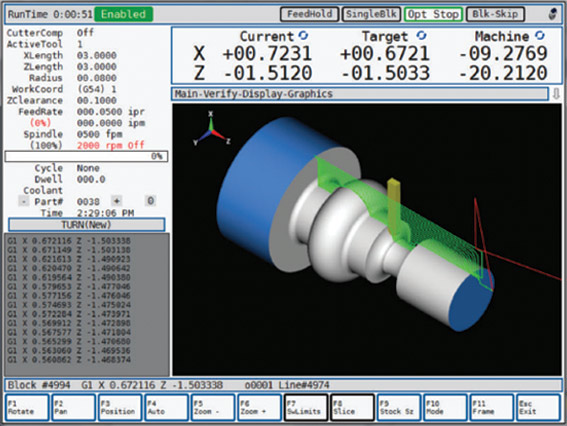

This is a high efficiency conversational turning strategy for use on all new Milltronics CNC lathes. Benefits include faster cycle times & reduced tool changes – Do more with one tool. Bi-Directional Turning takes advantage of the new tooling technology allowing you to cut both towards and away from the spindle. Not only does it eliminate retract and positioning moves in profiles, but it also allows you to do more with one tool with no need for individual profiling and grooving tools thus eliminating tool changes that cost you time. Bi-Directional cutting is smart turning for your new Milltronics lathe.

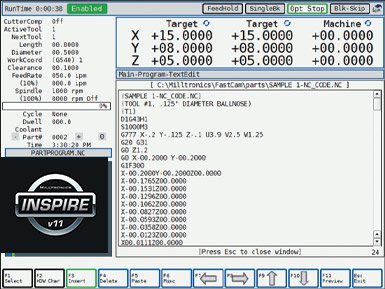

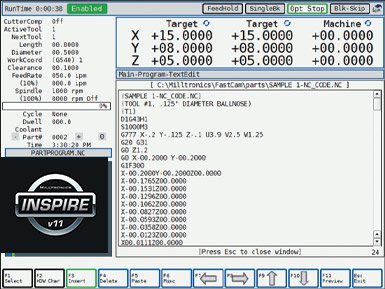

This patented control technology enables you to maximize cutting efficiency by managing the balance between speed and precision. Using a racecar analogy, MotionBoss™ allows you to set the width of the track along with the maximum speed. The INSPIRE control then determines the optimal path around the track, automatically accelerating between line segments or slowing down for a tight turn, providing you with a faster cutting time, less chatter, less vibration, and less machine jerk.

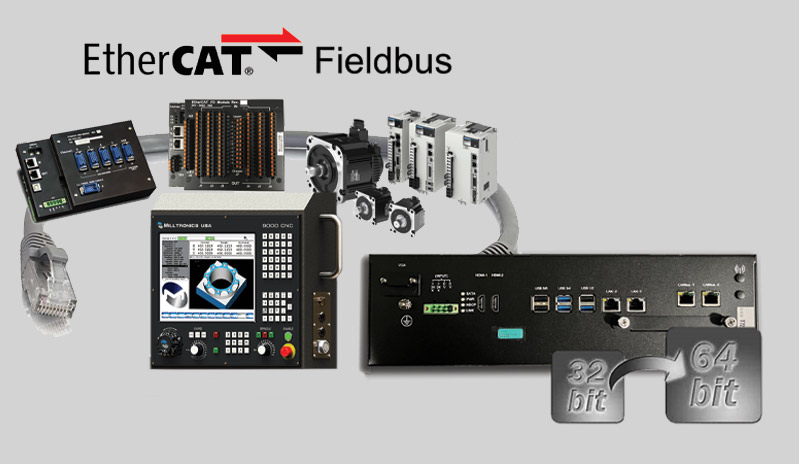

With 4 times the memory capacity, 20 times the GPU memory, faster processing capabilities, improved graphics, and heightened reliability, our upgraded systems stand out among the competition. Additionally, the streamlined design with fewer connections provides increased ease for technicians to service the machine if needed

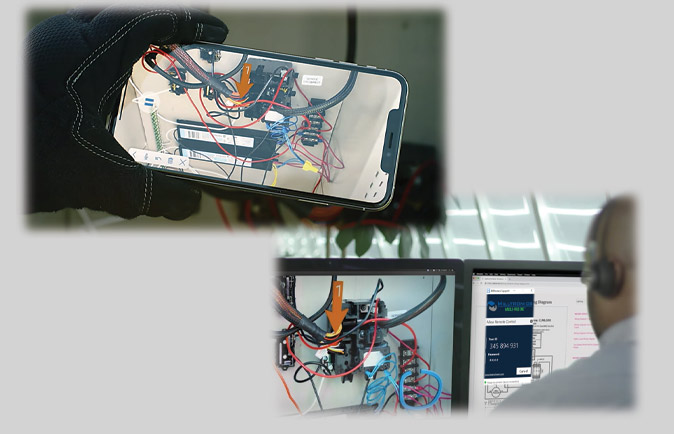

With INSPIRE v11, our latest software offering empowers customers with an array of cutting-edge features, including the integration of TeamViewer. This innovative addition enables users to take advantage of interactive troubleshooting, remote PC access, augmented reality, faster real-time support, and direct access to product experts.

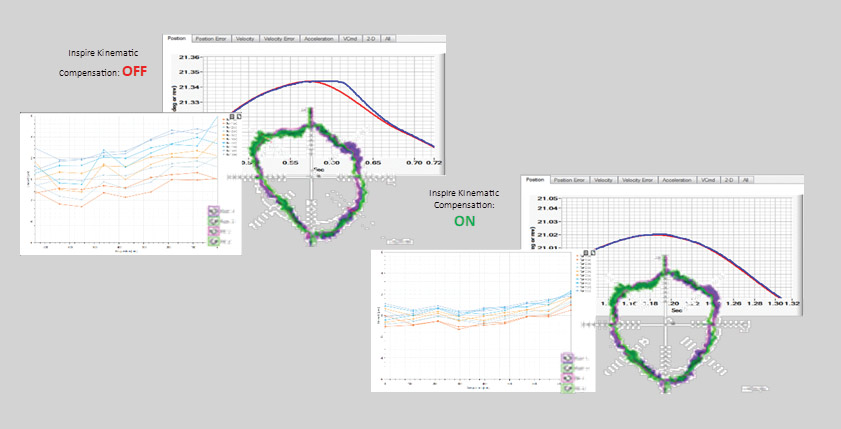

Inspire consolidates industry leading best practices compensation techniques into the control software ensuring you get the most from the solid, rigid mechanical foundation detailed above. The Kinematic Compensation Suite includes ISO 230-2 multi-pass axial compensation for improved positional accuracy; reversal spike compensation to deal with sightlines on molds; squareness compensation to tweak perpendicularity of axes; and digital field bus communications eliminating drift and analog signal noise.