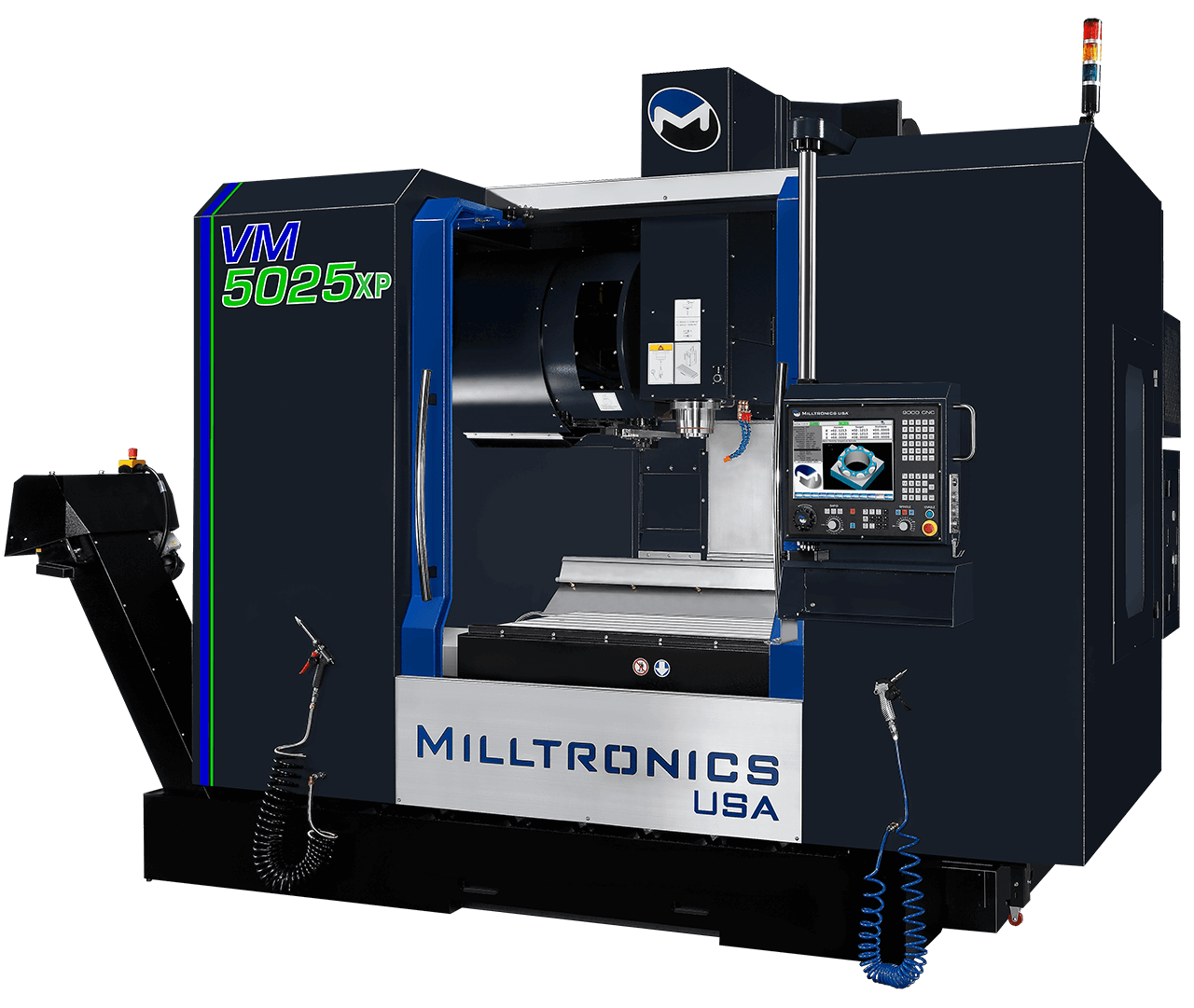

With generous travels of 50″ x 25″ x 24″ and a 54″ x 25″ table, the VM5025XP has a 35 HP dual wound 8,000 RPM spindle that produces 365 ft-lbs of torque.

The XP stands for extra power since these CNC machines are built with a 50 taper spindle and linear cross roller guides for rigidity, direct-coupled ballscrews for faster response, and dual wound spindle motors for faster acceleration/deceleration and more torque. Standard with up to 35 HP for maximum metal removal, the XP Series features a heavy duty belt drive spindle and also includes more standard features, such as a coolant ring and washdown system, lift-up chip conveyor, and height adjustment on the control.

With generous travels of 50″ x 25″ x 24″ and a 54″ x 25″ table, the VM5025XP has a 35 HP dual wound 8,000 RPM spindle that produces 365 ft-lbs of torque.

Our biggest XP Series machine at 60″ x 30″ x 24″, the VM6030XP has a 66″ x 30″ table and a 35 HP dual wound 8,000 RPM spindle that generates 365 ft-lbs of torque.

Our biggest XP Series machine at 84″ x 34″ x 30″, the VM8434XP has a 86″ x 34″ table and a 35 HP dual wound 8,000 RPM spindle that generates 365 ft-lbs of torque.