Don Hammer - Vice President

At Milltronics, we regularly see customers make the decision to take on tougher work. Many times, this is to take full advantage of their machine capabilities. If your machine can hold far higher tolerances than your current part mix demands, challenging yourself to maintain a greater degree of precision is rewarding and can lead to winning jobs that boost profitability. As shops make this transition, though, they often encounter an issue that they may not have previously considered: spindle growth.

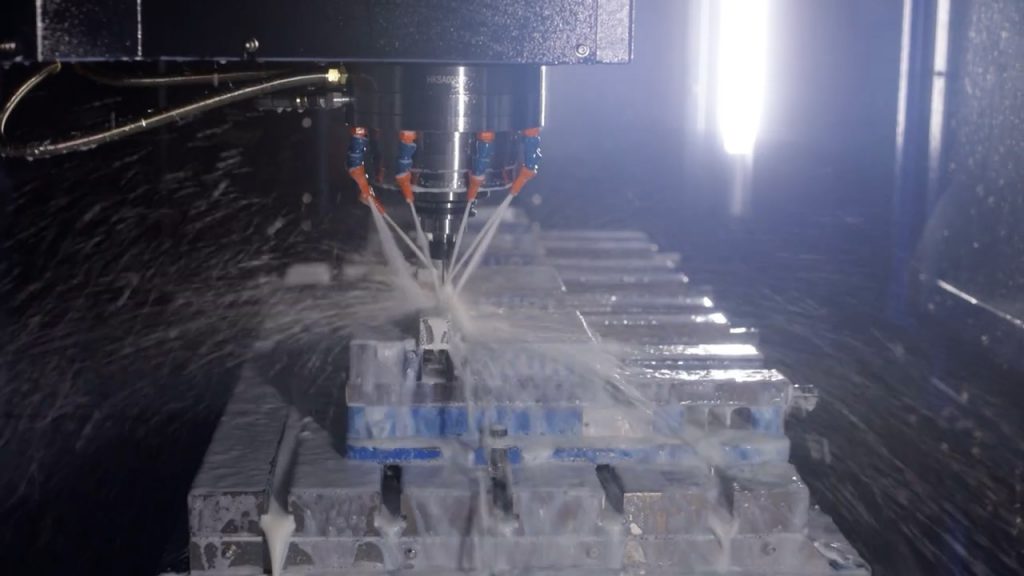

The physics behind the phenomenon are straightforward. Running a spindle generates a lot of heat. The spindle is made of steel. Steel expands when it absorbs heat. The end result is that the z-position of your tool can vary by up to 0.003″ due solely to that thermal expansion. While that might not be enough to cause problems with lower precision work, it can create real problems when dealing with more demanding tolerances or surface finishes.

Some shops attempt to tackle this problem by long warm-up cycles. That is, they’ll run the spindle for up to an hour before putting a tool in the cut. There are two big problems with this. Most importantly, cutting air doesn’t make chips and eats into the profit potential of your machine. Additionally, the level of heat generated by the spindle varies due to factors such as the utilization rate and aggressiveness of the cut. Even a warmed-up spindle will see some slight variation as it processes a part, potentially to a degree that will cause the finished part to be out of spec.

Fortunately, there’s a far better and easier solution. Many modern machine tools, including those from Milltronics, can be equipped with software that automatically counters thermal growth. Using sensors already located in the spindle, this software add-on automatically calculates the level of thermal expansion and adjusts the Z axis accordingly. This eliminates both guesswork and waste.

It’s worth noting that for parts with extremely high tolerances, the spindle can be impacted even beyond the heat that it generates. A shop environment that’s cooler in the morning and heats up in the afternoon will experience spindle growth. Thermal compensation software eliminates that potential problem as well.

If your growth plan includes taking on more demanding work and you want to make thermal expansion a non-issue, contact our team today. With a quick and inexpensive upgrade to your machine, you’ll be able to produce high-tolerance work with far greater confidence!

During his 17-plus years with Milltronics, Don Hammer has worked his way up from engineering to Vice President. You can reach him at [email protected].